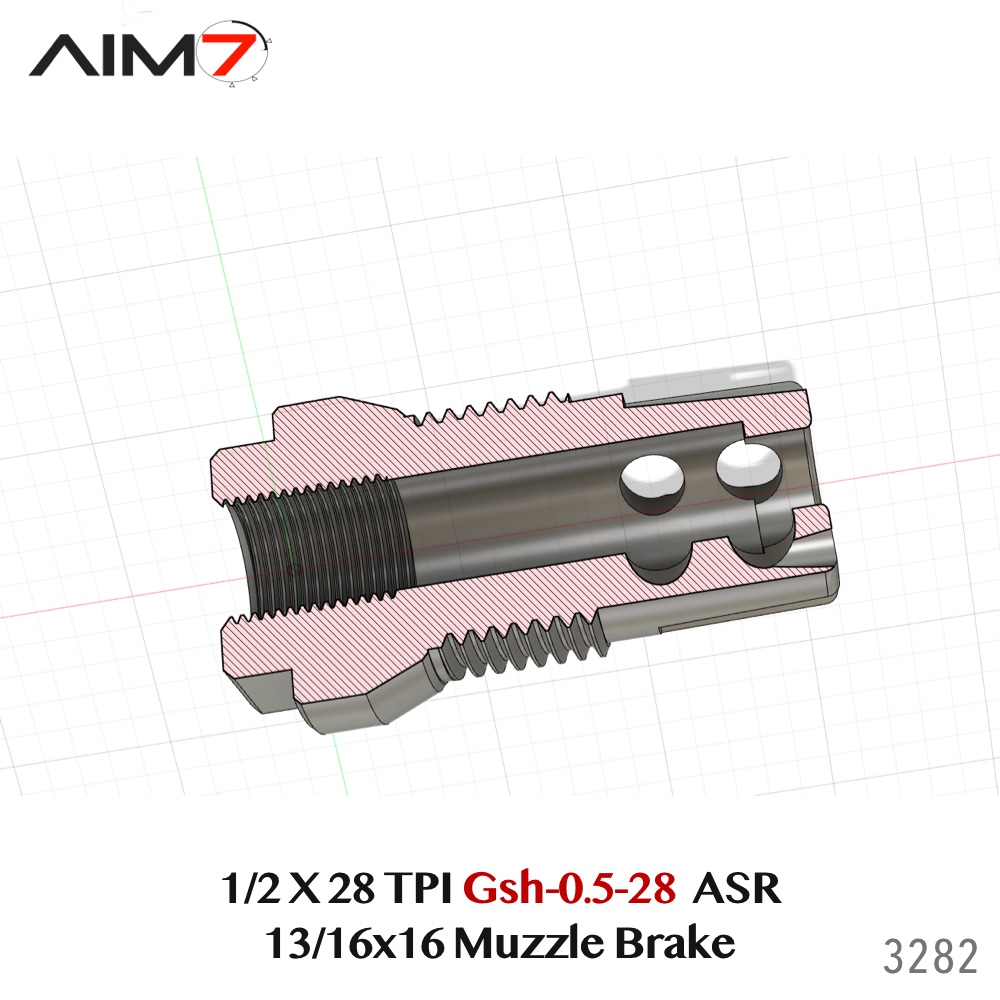

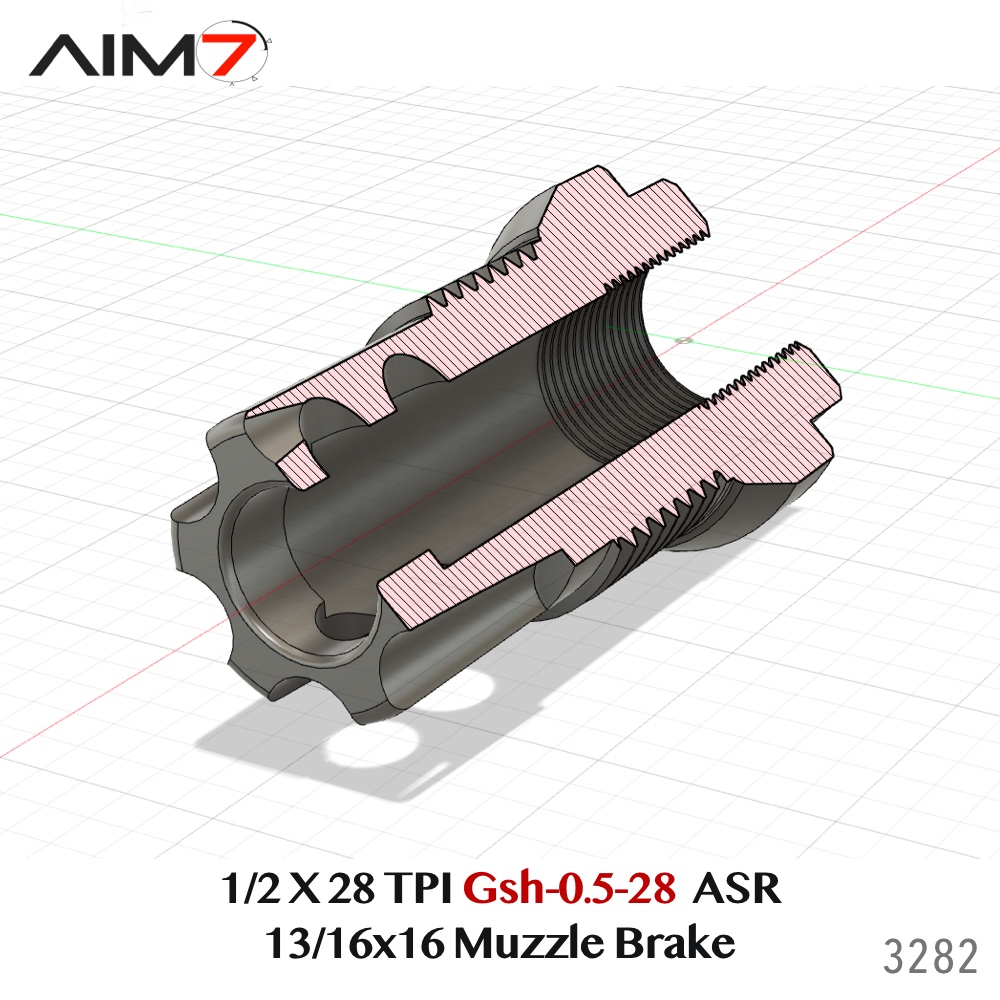

AIM7 Gsh-0.5-28 ASR Muzzle Brake 1/2 x28″ .223/556/9mm

Description

AIM7 Gsh-0.5-28 ASR Muzzle Brake 1/2 x28″ .223/556/9mm/22LR

The AIM7 Gsh-0.5-28 ASR Muzzle Brake is a 1/2×28 threaded muzzle device designed for compatibility with the SilencerCo ASR (Active Spring Retention) mounting system. This allows for quick attachment and detachment of compatible suppressors, enhancing versatility for shooters.

🔧 Key Features

Thread Pitch: 1/2×28, suitable for calibers like .223 Remington, 5.56 NATO, and .22LR.

ASR Compatibility: Designed to work seamlessly with SilencerCo’s ASR mounting system, facilitating rapid suppressor attachment.

Material: While specific material details for the AIM7 Gsh-0.5-28 are limited, similar AIM7 models utilize SUS303 stainless steel, known for its corrosion resistance and machinability.

⚠️ Important Considerations

Caliber Compatibility: Ensure the muzzle brake’s bore diameter matches your firearm’s caliber. For instance, a brake designed for .223/5.56 with a 9mm firearm can be unsafe due to the larger bullet diameter.

Suppressor Mounting: If you plan to use a suppressor, verify that both the muzzle brake and suppressor are compatible in terms of thread pitch and mounting systems.

🔍 Additional Information

While specific details on the AIM7 Gsh-0.5-28 ASR Muzzle Brake are scarce, similar products like the SilencerCo ASR Muzzle Brake offer insights into the ASR system’s functionality. The SilencerCo ASR Muzzle Brake features a 3-port design to reduce recoil and muzzle climb and is compatible with various thread pitches and calibers.

- Overall: 1.80″

- Outside Thread Pitch: 13/16×16

- Bore Size:0.38″

If your AIM7 muzzle brake is made from SUS303, it’s well-suited for semi-auto civilian use on .223/5.56 rifles, including suppressed setups via the ASR system.

It offers good performance at a reasonable price, but isn’t built for the most extreme military-grade abuse.

Equivalent: AISI 303

| Property | Description |

|---|---|

| Composition | Iron, ~17–19% Chromium, ~8–10% Nickel, ~0.15% Sulfur, ~1% Manganese |

| Machinability | Excellent – sulfur makes it easy to machine (better than SUS304) |

| Corrosion Resistance | Good, but slightly lower than SUS304 due to sulfur content |

| Tensile Strength | Moderate (~500–750 MPa depending on treatment) |

| Weldability | Poor – sulfur causes cracks and inclusions when welded |

| Magnetism | Non-magnetic in annealed condition |